Self-assembly of slatted floors for pigsties

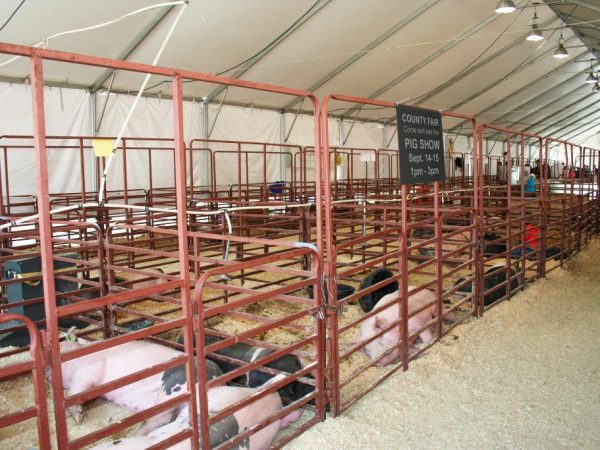

In many ways, the success of pig breeding depends on the cleanliness of the room in which they are kept. The building must comply with all sanitary and hygienic standards and be easy to use.

Installation of slatted floors for pigsties

Slatted floors for pigsties are considered the most optimal option from the point of view of hygiene and have many advantages over continuous flooring. Such structures consist of two levels, which ensures the preservation of heat even in the most severe frosts and allows you to automate the cleaning of animal waste products.

Quality requirements and benefits

Slotted floors for pigsties are divided into several types, depending on the material from which the structure is made:

- concrete;

- plastic;

- metal.

From a hygiene point of view, the slatted floor meets all the prescribed standards. The cover allows for unimpeded collection of faeces by automating the process. The materials are easy to clean, do not deteriorate due to the use of pest control agents, and are completely safe for pigs. When installing such structures, the frequency of infectious diseases among the livestock is significantly reduced.

Among other things, the use of such a floor can significantly reduce the cost of heating devices. Slotted floors can reduce water consumption for cleaning by 5 times. The main thing is that such designs are suitable for both large pig farms and small sheds for several heads and can be made by hand. The material for the slatted floor is selected depending on what kind of animals will be kept in the room.

Concrete structures

On large pig farms, concrete slatted floors are most often made. This design is capable of withstanding a large mass. Compared to other flooring, concrete slatted pigsty floors are the strongest and most durable. The material does not absorb odors and does not deteriorate under the influence of pig waste products.

The price of concrete slatted floors is quite high, plus do-it-yourself installation of the structure requires a lot of effort and certain skills in construction. Special construction equipment is required to lay this type of coating. Only adults can be kept on such a floor; piglets need warmer material.

Concrete slatted floors can withstand up to 600 kg of load per square. With all the desire to do such a design with your own hands, it is very difficult to do it yourself. An alternative to a concrete screed is the purchase of ready-made reinforced concrete slabs.

Plastic constructions

Plastic slatted floors began to be used not so long ago, but they managed to win the hearts of many breeders due to their affordable price and ease of installation. Installation of a plastic slotted floor does not require special skills.This flooring is non-slip and has high hygienic qualities.

Plastic slatted floors are perfect for keeping young pigs of suckling age. The design has a fractional relief, so even the smallest piglet will not be able to get injured when moving on such a floor. Used to keep pigs in the middle weight category.

You can buy plastic shields only ready-made. Making them with your own hands simply will not work. The fasteners are interconnected at the casting stage.

Metal constructions

In some cases, metal structures are used. Most often sows are kept on such floors during lactation. During active milk production, females become restless and aggressive, and the coolness of the metal has a calming effect on them. Steel partitions are made from:

- cast iron;

- galvanized sheets.

A metal slatted floor can be made by hand. For this you need a welding machine. To keep piglets on such floors, it is necessary to equip the building with a heating system.

Manure removal automation

The slatted floor for pigsties implies the equipment of a self-alloy system for removing faeces. After laying the foundation, special baths are installed, to which the sewer main is supplied. Above the baths, a slatted floor of the selected material is placed. There are 2 methods for installing slatted floors:

- when the grill is located around the entire perimeter of the floor;

- part of the floor is slatted, and part is solid.

Continuous slatted floors around the perimeter are used for large pig farms. The design implies the equipment of the coating with a heating system. Such floors are designed for keeping a large livestock of pigs. Under the lattice plates, there are special tanks, into which the waste products of animals fall, coming from there into the drain pipe.

Waste products removal automation

Partially slotted floors differ from the previous design in that the cleaning process is not fully automated. Manure tanks are fitted with plugs. For some time, manure remains in liquid form in baths.

When filling the tanks, the slatted part of the floor covering is removed and the faeces are pumped out of the bowls into the sewer after opening the plug. The second method of installation allows you to significantly save on the purchase of lattice plates. Pigs go to the toilet in one place, so in small private estates it makes no sense to install continuous slatted floors.

Manufacturing technology requirements

A slit floor for pigs must correspond not only in quality and price, but also meet technological standards. When choosing a design, you should pay attention to durability. The floor covering will be under constant mechanical stress during the movement of heavy animals. The waste products of the pigs cause a considerable amount of damage.

Perhaps the most important characteristic for a slatted floor is the safety of the structure for animals of all ages. To prevent pigs of any age from being injured while moving, it is recommended to buy or make your own cells 10 x 150 mm. The health of animals will directly depend on the material from which the structures will be made. It is recommended to use only hygroscopic and environmentally friendly materials.

Installation rules

The very first thing to do when constructing a building after laying the foundation is flooring. This applies not only to the construction of a new building, but also to renovation. When installing the flooring, there is a high likelihood of damage to the rest of the pigsty.

The strength of the foundation and its waterproofing are the paramount points to which you should pay attention.The alkaline environment of waste products is a very aggressive destroyer. If you do not take care of the strength of the foundation in advance, and use low-quality materials, the building can subsequently shrink heavily, as a result - additional costs for its reconstruction.

Reservoirs for collecting faeces should not be lower than 60 cm. Bitumen is used as a waterproofing material for sealing gaps on the surfaces of reservoirs and channels. It is very important to select slatted floors at the design stage. This will make it possible to calculate the pressure on the foundation. For example, a concrete structure will have a greater impact on the foundation than a plastic one.

Final part

Strong concrete slatted floors for pigs are a must. When building pig farms, small and large, an important place is given to the arrangement of the floor. It is on the floor that the animals will go to defecate, so the health of the livestock will directly depend on its quality. Slatted floors are the best option, which allows you to fully or partially automate the removal of faeces from the pigsty. The price of a floor covering will depend entirely on the material from which it is made.

Today, plastic slatted floors are quite popular. They are characterized by low hygroscopicity and can support animals of average weight. The price of such a cover is more than acceptable, and the ease of installation makes them ideal for keeping a small number of livestock.

For large pig farms, it is recommended to use concrete or metal slotted slabs, installing an additional heating system. Such a coating can withstand a weight of up to 600 kg. Before installing the coating, you need to pay attention to the foundation of the building. It must be well waterproofed and reinforced.